Understanding Colour Printing

Colour printing is the process where illustrative materials are produced in colour on the printed page. Colour printing uses yellow, magenta, black and cyan ink (CMYK) to produce various colours by subtractive mixing to give the red, blue and green colours.

To print on a four-colour press, all RGB files must be converted into CMYK colours. Converting your colour image file from RGB to CMYK is an important step in prepress preparation of digital files.

Scanners and digital cameras create images using the three primary colours of light—red, green and blue. An image printed on a press typically uses four colours—cyan, magenta, yellow and black. For best results when designing your artwork for printing start with CMYK colour mode.

The earliest colour print in the world can be traced back to China, in the form of a 2-colour Buddhist sutra scroll, that is dated back to 1346. The earliest way to add colour to printed materials was by colouring by hand. This technique was used in Asia and Europe to bring printed images to life and give viewers something even more visually appealing to look at on the printed page.

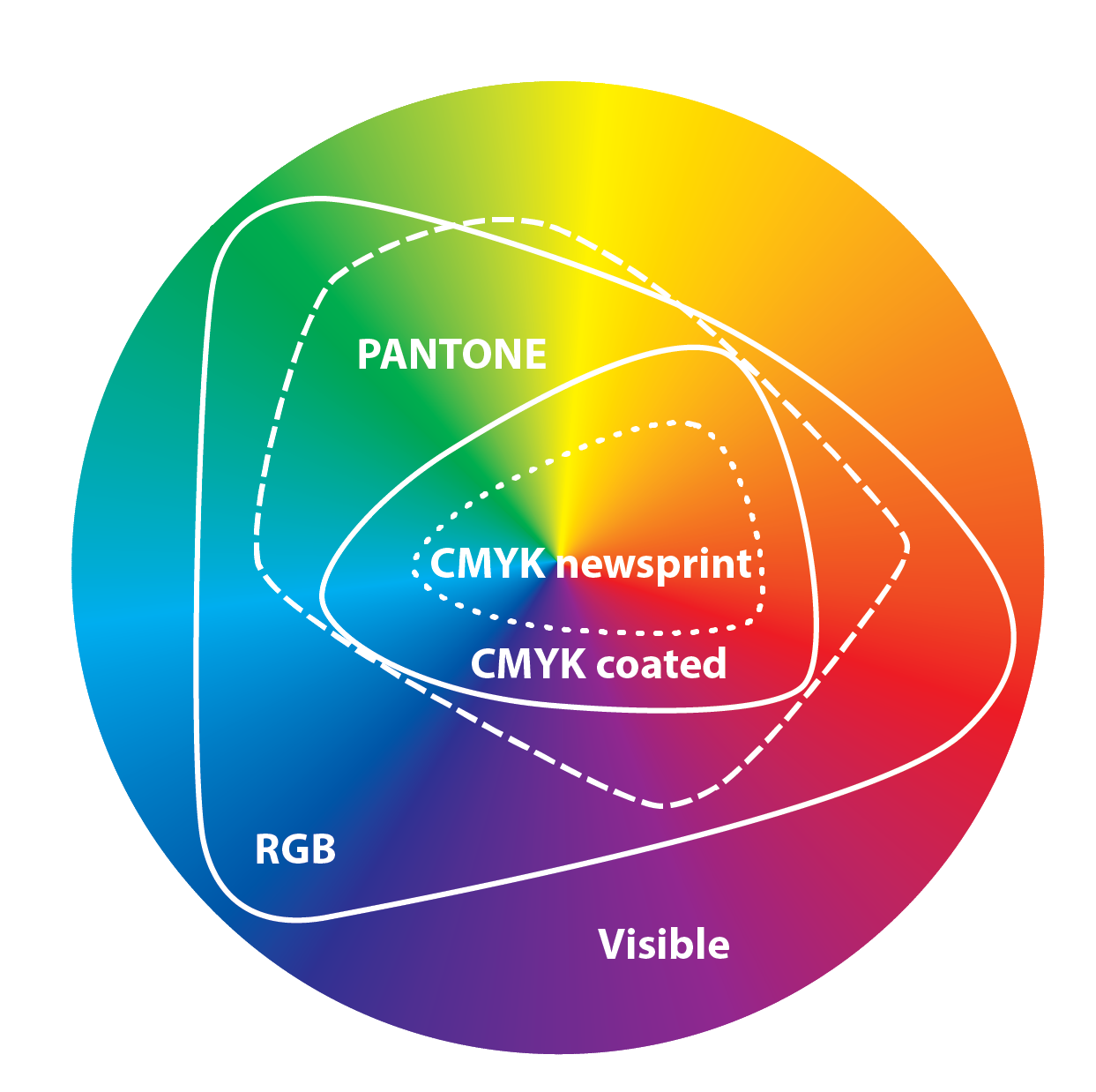

1. Understand the gamut

A colour gamut is a subset of colours, such as those in a specific colour space. Every device and printing process e.g. colour printer, camera, scanner, monitor etc has its own set of colours that it can successfully reproduce.

A colour gamut is used to make these differences clear as well as show what colours they all have in common. Your colour options depend on what you’re working with. The RGB screen will let you mix very bright and saturated colours, but if you need to print your designs then your options change due to the limited colour spectrum of a CMYK printer.

Similarly, if you see a brochure printed with vibrant Panton colours, you won’t find them on screen as they can’t be represented on an RGB monitor.

2. Learn about additive and subtractive mixing

There are two ways to go about creating the colour— either by mixing light (additive) or by mixing paint on paper (subtractive). Additive mixing is all about combining red, green and blue light sources in various intensities. So the more light you add the brighter your colour mix becomes which is the way we are used to mixing colours through the RGB computer model.

But before TVs and computer monitors, printers and publishers were using subtractive colour mixing which was the norm. This is where you subtract light from the paper by adding more colour.

Originally, it was just red, yellow and blue that were used in the subtractive process but as printing emerged, these were replaced with cyan, magenta, yellow and black (CMYK) enabling printers to produce a larger variety of colours on paper.

3. Practical Tips

Designers face key challenges in colour printing, including the shift in colours during RGB-to-CMYK conversion and the need to handle out-of-gamut colours effectively. Maintaining colour accuracy involves regular monitor calibration using hardware tools and the application of standardized colour profiles across design software and printing devices.

When printing vibrant colours on different materials, designers must understand material characteristics, conduct test prints, and adjust settings accordingly to achieve optimal colour intensity.

Best practices include using high-resolution images and embedding fonts and graphics to avoid substitution issues.

Effective communication with printing professionals provides valuable insights into colour considerations for specific materials and processes, ensuring accurate and vibrant results in the final print.

4. Industry Trends

Recent trends in colour printing technology have witnessed notable advancements focused on enhancing colour accuracy, introducing innovative ink formulations, and adopting emerging standards.

One prominent trend is the development of high-precision colour calibration tools and software, enabling printers to achieve more accurate and consistent colour reproduction. This advancement is particularly crucial in industries where precise colour matching is paramount, such as packaging and branding.

Ink formulations have also evolved, with a growing emphasis on eco-friendly and sustainable options. Manufacturers are exploring new formulations that reduce environmental impact without compromising colour vibrancy and quality.

Additionally, there’s a rising interest in speciality inks, such as metallic and fluorescent inks, offering designers more creative possibilities.

Emerging standards, including expanded colour gamuts like the Pantone Extended Gamut (PANTONE® Goe™), aim to provide a broader range of reproducible colours, pushing the boundaries of what is achievable in colour printing.

These trends collectively contribute to a more sophisticated and environmentally conscious landscape in the field of colour printing technology.

5. Printing Technology

Each printing technology has its strengths and considerations when it comes to colour reproduction. Factors like ink type, substrate, and printing method play crucial roles in determining the final colour output.

Designers should be aware of the specific characteristics of the chosen printing technology to optimize colour accuracy and achieve the desired visual impact in their printed materials.

5.1. Inkjet Printing

Inkjet printing propels droplets of ink onto the printing surface. It is commonly used in both desktop and industrial printing applications.

Impact on Color Reproduction- Inkjet technology provides vibrant colour reproduction with high resolution. Advanced ink formulations and colour management systems contribute to accurate and consistent colour output.

5.2. Offset Printing

Offset printing involves transferring ink from a plate to a rubber blanket and then onto the printing surface. It is commonly used for large-scale, high-volume printing.

Impact on Color Reproduction- Offset printing typically achieves high-quality colour reproduction using CMYK inks. Colour accuracy is influenced by factors like ink consistency, paper type, and plate quality.

5.3. Digital Printing

Digital printing directly applies ink to the printing surface without the need for plates. It is suitable for short to medium print runs and offers variable data printing capabilities.

Impact on Colour Reproduction- Digital printing provides quick turnaround times and allows for more precise colour control. However, colour consistency may vary across different machines, and achieving specific colours may be influenced by the printer’s technology and calibration.

5.4. Laser Printing

Laser printing employs electrostatic processes, utilising a laser to create an electrostatic image on a photosensitive drum. Monochrome laser printers excel in producing high-quality black and grayscale prints, while colour laser printers use CMYK toner cartridges to achieve vibrant and precise colour reproduction.

Impact on Colour Reproduction- Laser printing’s impact on colour reproduction is marked by its efficiency, versatility, and ability to consistently produce accurate and saturated colours, making it a popular choice for both text and graphics in professional settings.

One Comment